UPCYCLING

PLASTIC STRAWS

This project aimed at exploring the secondary but unique properties of straws such as porosity, light weightedness, slipperiness, cushiony/rounded, strong, etc. through interlacing them structurally on a loom. Various material and weaving technique combinations are used to make sample surfaces without changing the chemical properties giving them potentially a sustaining second life.

Sample 1

Weave- Honeycomb

Warp- straw

Weft- Sturdy metal wires

Concept- Combination of woven sturdy wires and straws forming big and strong honeycomb unit (6”x 2”) structure.

Warp- straw

Weft- Sturdy metal wires

Concept- Combination of woven sturdy wires and straws forming big and strong honeycomb unit (6”x 2”) structure.

Sample 2

Technique- Double Cloth (plane weave)

Warp- straw (3 metal wires inserted between the straws)

Weft- straw

Concept- The bottom layer is not woven after a point. So that the top layer can bend and give a shed to it.

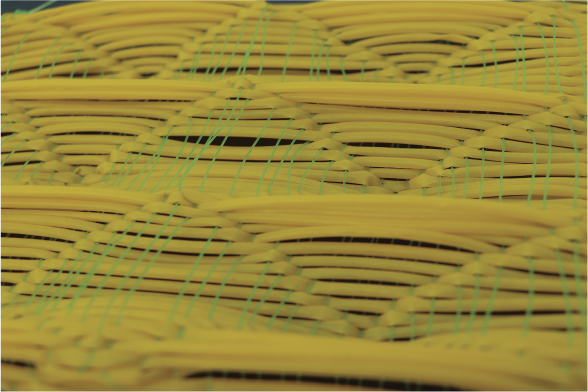

Sample 3

Technique- Double Cloth (honeycomb+ plane)

Warp- straw (metal wires inserted at the topmost layer of honeycomb)

Weft- straw (metal wires inserted at the topmost layer of honeycomb)

Concept- Metal frame forms perfect rectangular units with evident depth to each unit. The bottom layer acts as a supporting layer to the units.

Sample 4

Weave- Honeycomb

Warp- straw

Weft- nylon

Concept- Bigger honeycomb units gives a significant hight to the sample. Thin nylon weft tends to hold the structure together.

︎︎︎

Back to Top2 weeks, Personal, exploratory project (2019)