WOVEN SENTIENCE

︎

3D WEAVING

A sensorial interface

This thesis Introduces an ecosystem of 3D woven technology that challenges conventions of materiality. By re-imagining woven structures as adaptable, resilient and conductive, this project explores how advance material composition can transform seamlessly across industries from wearables, furniture to outer space and beyond.

This work speculates on the future of woven materials as intelligent systems that not only provide structural integrity but also embed monitoring capabilities.

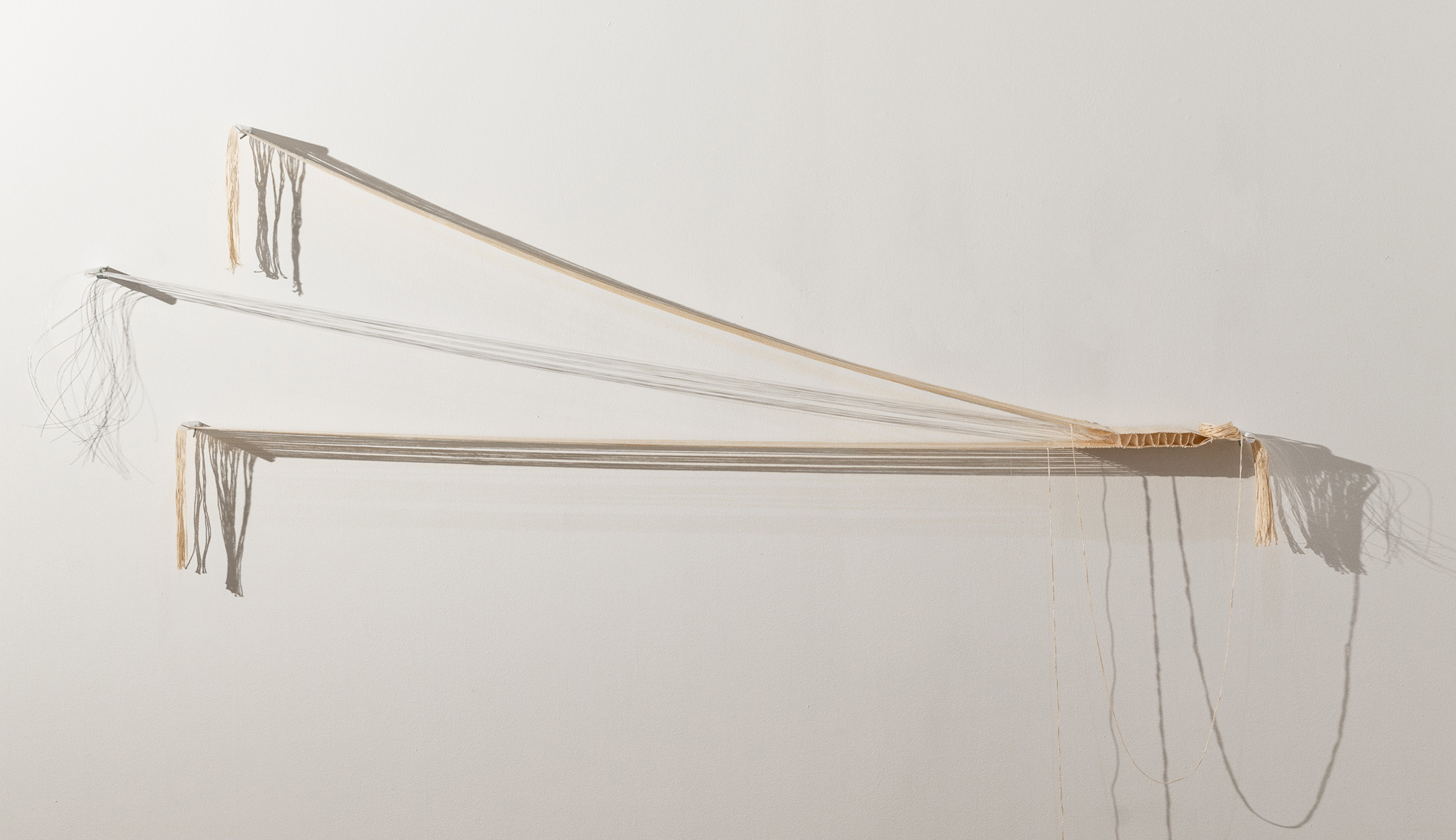

Pressure sensitive woven piece

Series of various 3D woven pieces with pertaining animations exhibited at SAIC galleries, Chicago

The Craft

Making of the matetial is core of this technology. By altering traditional craft of weaving with un-conventnal and conductive yarns in an advance composition, this project transforms materials as an active and responsive medium.

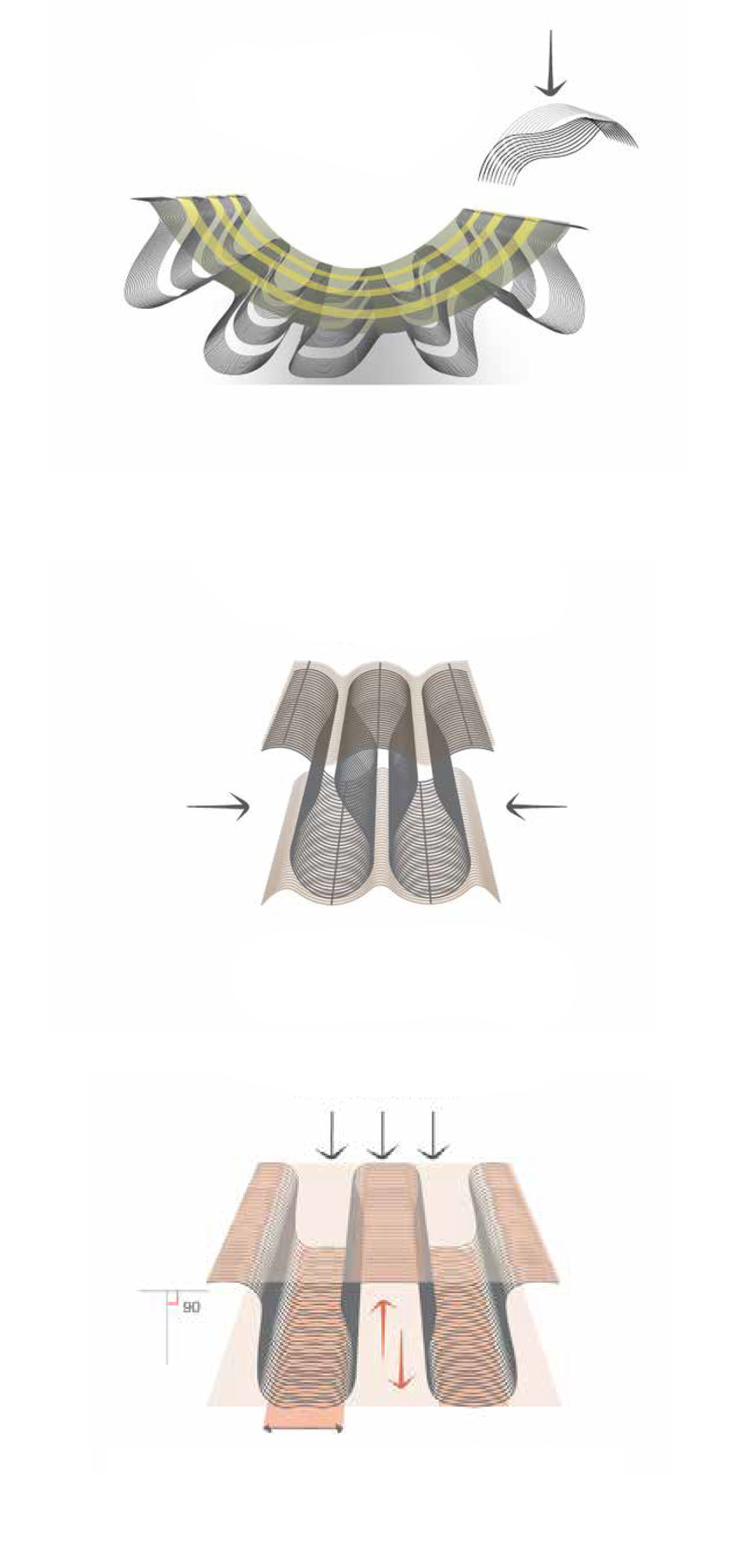

Cross-sectional view of the weave and the weaving process,

also exhibited at SAIC galleries, Chicago

also exhibited at SAIC galleries, Chicago

3D weaving process

Structural Properties

The structural adaptability of this craft lies in it’s internal configuration; by altering the weave’s density, scale, and materials, the same product can serve vastly different functions. Ranging from prolonged ergonomic support and posture correction to monitoring external impact on the body in extreme environments.

The volumetric nature of the weave offers inherent benefits such as impact isolation, acoustic absorption, and spatial buffering. These qualities make the material adaptable across diverse environments—from protective gear to architectural and interior systems

The volumetric nature of the weave offers inherent benefits such as impact isolation, acoustic absorption, and spatial buffering. These qualities make the material adaptable across diverse environments—from protective gear to architectural and interior systems

Few of the many mechanical properties

Performance

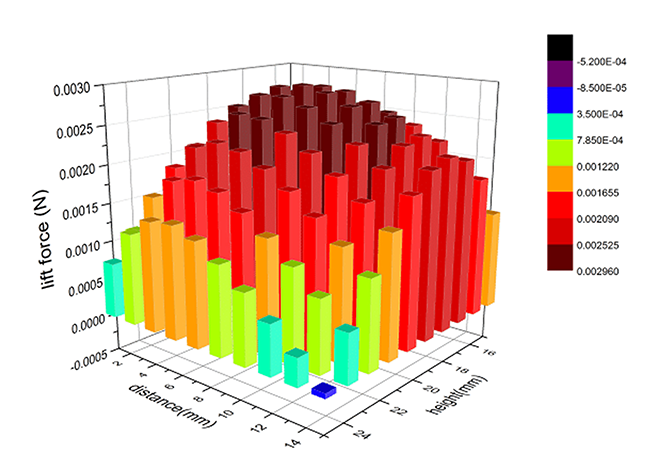

The performance of this 3D woven material lies in its holistic and self-sufficient architecture. Each structure functions as an intelligent, parallel environment—capable of sensing pressure, monitoring force distribution, intensity, and identifying potential pain points in real time.

This makes it valuable not only for cautionary applications, such as detecting risk of injuries, but also as a training tool that visualizes movement patterns through a single woven matrix.

Force vs resistance (in yarns) graph

Animation speculating some of the future implications

Graph determining the force on the 3-dimensional surface.

This thesis is formulated as part of my Master’s in Designed Objects

at School of The Art Institute of Chicago | 2023-25

Mentor: Ben Stagl, Ceci Gomez & Eric Hochkiss